6000 Series Industrial Aluminum /Aluminium Alloy Extruded/Extrusions Profiles for Industry

Aluminium Extrusion Profile 40x40 TSlot 8 mm (200 mm) Buy Online in Singapore at desertcart.sg

In closing, extrusion aluminum sections are versatile and ideal for use in building automation applications, and aluminum is an excellent structural material, which lends itself perfectly for use in profile extrusions. More likely than not, there is an aluminum profile that's perfectly tailored to the specific automation application.

Buy 6063 Aluminum Alloy Aluminium Profile Extrusion Price,Size,Weight,Model,Width

Let Orange manage your aluminum extrusion programs for you. Learn more. Looking for top-quality stock aluminum extrusions profiles? We specialize in aluminum extrusions of all shapes and sizes, including custom designs to meet your specific needs. Whether you're looking for standard extrusions or customized solutions, we're here to help.

Where To Buy Aluminum Extrusions For Table Saw Fences Resource Guide

Aluminum Extrusion: An Important Manufacturing Process The aluminum extrusion process is essential for producing parts with custom cross-sectional profiles. The process is quite interesting, and you can get various shapes of products that you can heat treat, fabricate, and finish to specification.

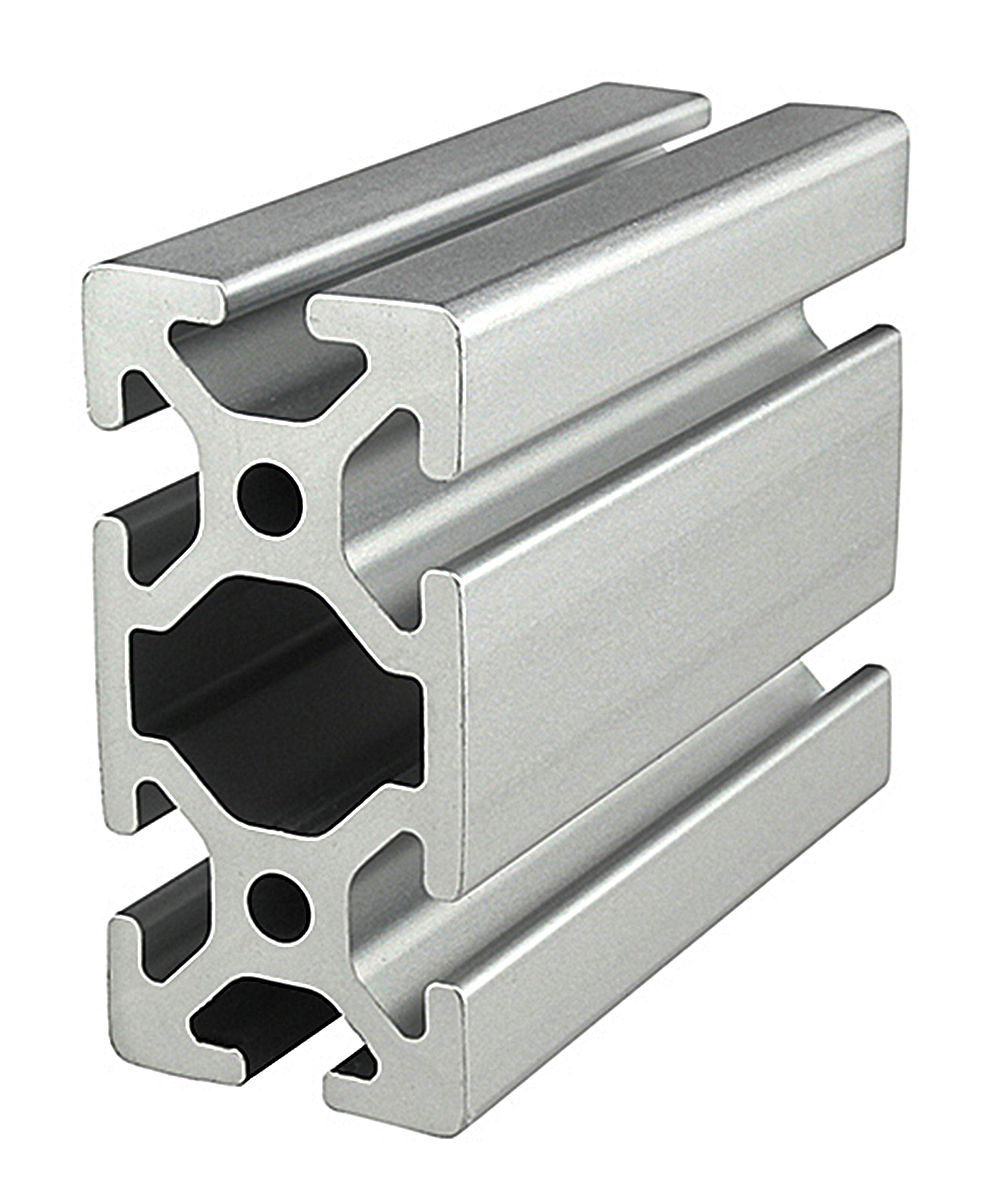

Machifit 400mm Length 4040 T Slot Aluminum Profiles Extrusion Frame For CNC

Choose from our selection of aluminum extrusions, including T-slotted framing rails, T-slotted framing structural brackets, and more.. T-Slotted Framing Rail Profile. Single. Double. Triple. Quad. System of Measurement. Inch. Metric. Rail Height. 5/64" 0.595" 1" 1 1/2" 2" 3". It is often used as a replacement for 2024 aluminum because it.

15+ Extrusion Aluminium

Aluminum extrusion is a process by which aluminum alloy material is forced through a die with a specific cross-sectional profile. Aluminum extrusion can be likened to squeezing toothpaste from a tube. A powerful ram pushes the aluminum through the die and it emerges from the die opening. When it does, it comes out in the same shape as the die.

15 Series Aluminum Extrusion Profiles T Slot Framing Air Inc

Discover Eagle Aluminum's extensive collection of aluminum extrusion profiles in our printable catalog PDF. Browse a range of extruded shapes & designs. Skip to content. Wishlist ; Eagle Catalog; Request Quote; [email protected]; 1-800-888-2044; [email protected]; 1-800-888-2044;

2040 aluminum extrusion profile european standard 2040 vslot black length 500mm aluminum

Custom Miniature Aluminum Extrusions. Profile Precision Extrusions highly-skilled team takes great pride in their ability to produce the most complex aluminum extrusion designs from a wide variety of industries. Our team is second to none, which has made Profile a recognized industry leader for manufacturing aluminum extruded tubing and shapes.

6000 Series Industrial Aluminum /Aluminium Alloy Extruded/Extrusions Profiles for Industry

The extrusion process shapes aluminum by heating it and forcing it with a hydraulic ram through a shaped opening in a die. Extruded material emerges as a long piece with the same profile as the die opening. Extrusion dies (steel disks) can be made to form nearly any shape or size. Some dies are flat and produce flat, solid profiles.

Basics of Aluminium Extrusion Bending Profile Design Alubend

T-Slots, aluminum extrusions, and parts. Architectural solutions and frames for industrial machine guards, workstations, data center enclosures, and more. Build your idea with 80/20 today.. One of the many benefits you'll find with 80/20 profiles and parts is its versatility. From machine guards to robot arms and racing simulators to.

Aluminium Extrusion Aluminium Profiles Extruded Aluminium China Aluminium Extrusions and

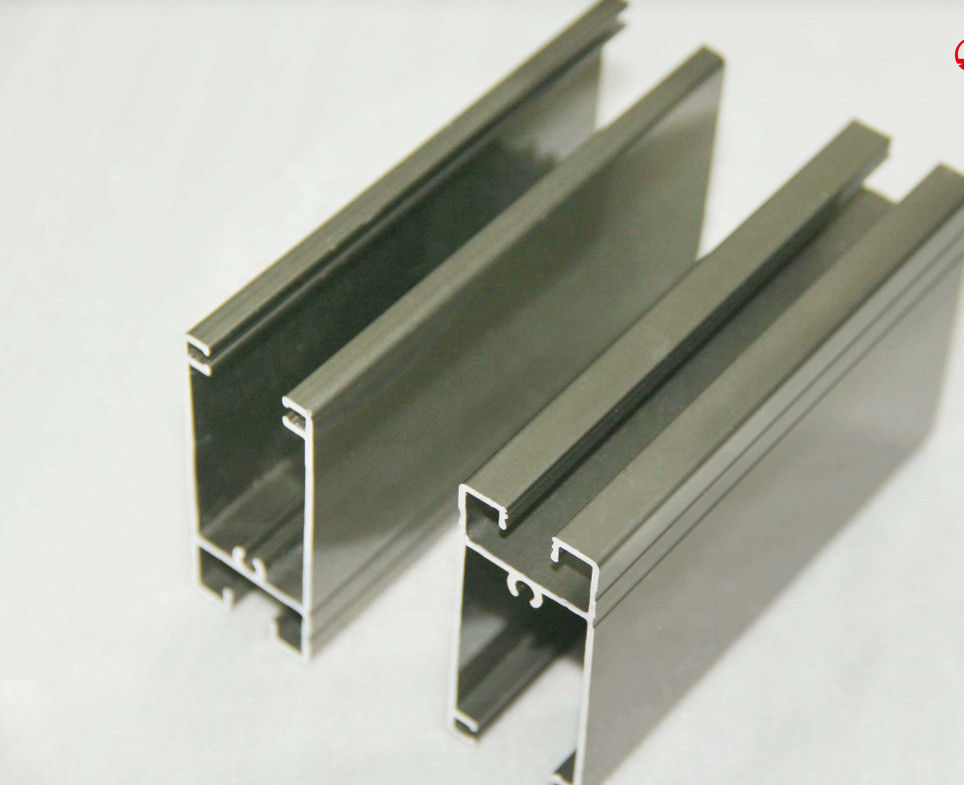

Our standard aluminum extrusion profile catalog features standard extrusions which includes rod, bar, angles, channel, beams, tees, Hex, Z-bar, pipe, tube and a variety of store front and flush glaze systems and accessories. At Tri-State Aluminum, we are a full-service supplier of standard and custom 6000 series aluminum extrusions made from a.

High Strength Standard Aluminum Extrusion Profiles 0.8mm Thickness

1.1 Aluminium profile forming processes. Extrusion. Process in which a billet in a container is forced under pressure through an aperture of a die (Fig. 1-1). Drawing. Pulling metal through a die in order to reduce or change the cross-section or to work harden the metal (Fig. 1-2). Cold roll forming (Fig. 1-3).

Types of Aluminum Extrusion Profile Extruded Aluminum Shapes Getec Industrial

Looking For Aluminum Extrusion Profile? We Have Almost Everything On eBay. Fast and Free Shipping On Many Items You Love On eBay.

How To Use Aluminum Extrusion? Unity Manufacture

The aluminum extrusion profiles feature intricate void spacing depending on the end use application. Here are the main types of aluminum extrusion profiles that you can choose from. Aluminum profile extrusion. Hollow Beam Profile. This is a variation of the aluminum square profile with a hollow interior that makes it light and strong.

TProfile 40mm X 80mm T Slot Aluminium Extrusion Profiles, For Industrial, Rs 850 /meter ID

If your aluminum trim isn't readily stocked, we know where to quickly find an existing shape you need. Eagle's aluminum extrusions manufacturer connections give you access to more than 10,000 custom aluminum profiles and extruded shapes. If you truly need a custom die and aluminum extrusion product, we will help you design and engineer it.

China Customized Aluminium/Aluminum Profile Extrusion with CNC Machining & Surface Treatment

Most aluminum extrusion profiles request only mill finish or clear anodizing surface for basic corrosion resistance. They emphasize the mechanical properties of aluminum material that can meet the application requests. Different aluminum alloy and temper is with different mechanical properties. There are 6060, 6063, 6061, 6082,.

Aluminium Profile from Matara UK InHouse Machining

The melting point of aluminum is approximately 1,220° Fahrenheit (660° Centigrade). Extrusion operations typically take place with billet heated to temperatures in excess of 700°F (375°C), and (depending upon the alloy being extruded) as high as 930°F (500°C). The actual extrusion process begins when the press ram starts applying pressure.